Overview

Overview

Applications

Applications

Process

Process

Bullet-proof Glass

Bullet-proof Glass

Overview

Overview

Overview

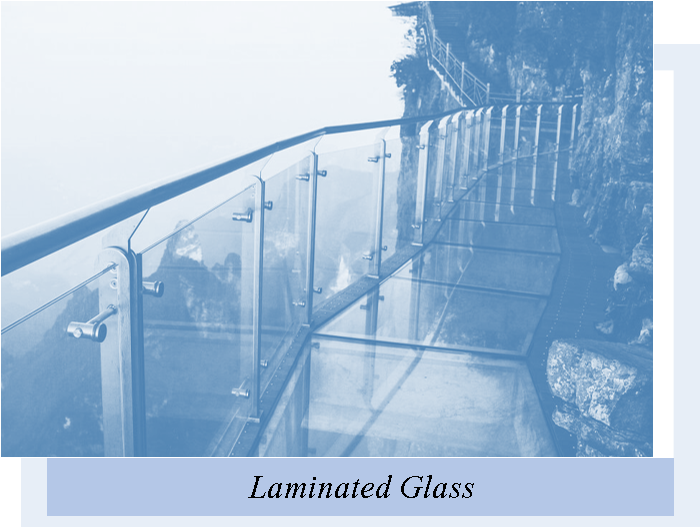

Laminated glass (LG) as a type of safety glass is considered a fantastic alternative to normal glass. It offers a tough, robust structure that is hard to break and holds together when shattered.

The reason for being held in place even in the case of breaking, is a thin polymer interlayer, typically of polyvinyl butyral (PVB), ethylene-vinyl acetate (EVA), lonoplast polymers, cast in place (CIP) liquid resin, or thermoplastic polyurethane (TPU), between its two or more layers of glass. The interlayer, made through heat and pressure, keeps the layers of glass bonded even when broken, and its high strength prevents the glass from breaking up into large sharp pieces. This produces a characteristic “spider web” cracking pattern when the impact is not enough to completely pierce the glass.

In the process of designing any building, safety along with beauty and comfort is of special and high priority. Considering the glass nature, the selection of thier usage in different parts of a building, needs accurate knowledge and attention.

Laminated glass, along with preserving the prper characteristics of light and energy, will protect the lives and property of residents of the building while protecting against natural disasters such as storms and earthquakes, as well as certain accidents such as theft, sabotage, shooting and explosion.

In addition to its specialized features, the glass also prevents ultraviolet rays from passing through and these issues will be explained in detail later.

Applications

Applications

Applications

So, the robust nature and thickness of laminated glass lend it a whole host of benefits:

Laminated glass provides a very strong, yet transparent layer with a variety of uses

Process

Process

Process

Modern laminated glass is produced by bonding two or more layers of ordinary annealed or tempered glass together with a plastic interlayer, usually polyvinyl butyral (PVB), Thermoplastic Polyurethane (TPU) or ethylene-vinyl acetate (cross-linked EVA). The interlayer is meant to improve the mechanical properties such as impact strength, fracture toughness, and failure modes in laminated glass. The plastic interlayer is sandwiched by the glass, which is then passed through a series of rollers or vacuum bagging systems to expel any air pockets. Then the assembly is heated for the initial melt. These assemblies are then heated under pressure in an autoclave (oven) to achieve the final bonded product (fully crosslinked in the case of the thermoset EVA).

Once a thermoset EVA is properly laminated during the process, the glass can be exposed frameless. There should be no water/moisture infiltration, very little discoloration, and no delamination. Newer developments have increased the thermoplastic family for the lamination of glass. Beside PVB, other important thermoplastic glass lamination materials today are ethylene-vinyl acetate (EVA), thermoset EVA, and thermoplastic polyurethane (TPU). The adhesion of TPU is not only high to glass, but also to polymeric interlayers. Since 2004, metallized and electroconductive polyethylene terephthalate (PET) interlayers are used as substrate for light emitting diodes and laminated to or between glass.

Bullet-proof Glass

Bullet-proof Glass

Bullet-proof Glass

Bulletproof glass is a laminet one in which, depending on the safety degree of glass, two or more layers of glass with special Pvb layers and suitable thicknesses are laminated. in the process of producing this product, the glass and polycarbonate are glued together at high pressure and heat so thatno seams remain between the layers. when the bullet hits the glass, the first layer of the glass is punctured, but the plastic layer absorbs the pressure of the bullet and stops it. In this way, the bullet can not reach the last layer of the glass.

Zarin Glass bulletproof glass test

Characteristics

This type of glass is quite resistant to shooting, so that after the bullet hit:

The classification of these glasses is based on the variety of weapons and ammunitions. The orientation of their installation is so significant in their function.

The Power of Quality

Sign up to receive our latest news:

All rights of this website belong to Zarin Glass co.

Design and Development: Nungar Processing